Container Homes: What They Don't Tell You (17 Years of Hard Lessons)

Container Homes: What They Don't Tell You (17 Years of Hard Lessons)

February 17, 2025

Just walked out of a $750K container home that made me want to quit this business. Beautiful couple, great architect, solid contractors—everything looked perfect on paper. Reality? I spent two hours in what felt like an expensive metal box that echoed like a canyon and couldn't hold a decent temperature to save its life.

Worst part? This happens all the damn time.

Been building these things since '08, back when mentioning "container homes" got you laughed out of construction meetings. Now? Can't keep up with demand. Problem is, most people jumping in have no idea what they're actually getting into.

Let me be clear: building luxury container homes ain't regular construction with fancy materials. It's not even tiny house construction. It's its own weird animal with rules that'll bite you in the ass if you ignore them.

Seventeen years of watching smart people make dumb mistakes taught me a few things. Time to share.

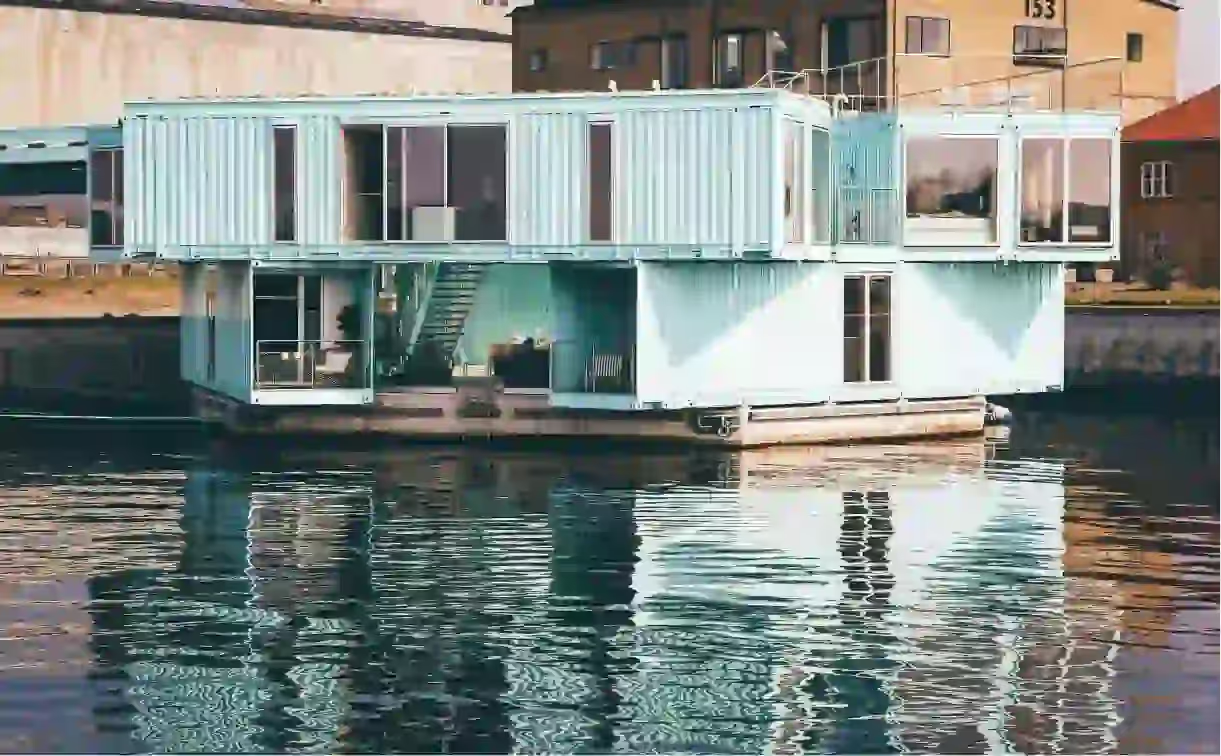

Rich People Discovered Shipping Containers

The change has been wild to watch. Five years ago, bringing up container homes at fancy dinner parties got polite nods and quick topic changes. Last week alone, three luxury builders called begging me to train their crews.

What happened? Simple—money got stupid expensive.

Construction Costs Lost Their Minds

Just quoted foundation and framing for a regular luxury build—$495K. That's not the whole house, just getting it out of the ground. Meanwhile, pristine 40-foot high-cube container? $6,800. Even my math-challenged clients can figure out that spread.

Here's the thing though—rich folks aren't using containers to build cheap. They're using them to build smart. That half-mil they didn't blow on basic structure? Goes toward the good stuff. Hand-carved cabinetry, Italian stone, German appliances that cost more than most people's cars, lighting systems straight out of museums.

**Industrial Meets Luxury (And It Works)

Something magic happens when raw steel meets high-end finishes. Those corrugated walls and clean lines create a backdrop regular construction can't touch. Tough but elegant. Minimal but dramatic.

Get it right, and nobody thinks "shipping container." They think "expensive architect." Which is exactly what's happening more and more.

Environmental Guilt That Actually Pays Off

Rich buyers today want homes that match their values. Container homes deliver real environmental benefits, not just feel-good marketing.

Every container we save from the scrap yard is tons of steel that doesn't need re-melting. Add solar, high-efficiency everything, and sustainable finishes—you're looking at carbon footprints that make regular luxury builds look embarrassing.

Seven Ways to Waste Your Money

Hundreds of builds later, I can spot disasters before they happen. These aren't little mistakes—they're expensive screwups that turn dreams into nightmares.

1. Trying to Fit Everything You've Ever Seen

Kills more projects than anything else. People browse container photos online and want every cool feature they've ever seen, whether it makes sense or not.

Toured one disaster where owners crammed in exposed brick, reclaimed wood ceilings, living walls, industrial lights, geometric rugs, statement art, and furniture from four different eras. Each piece looked great alone. Together? Like a design store exploded.

Small spaces magnify everything. That sectional that disappears in a 2,500-square-foot room becomes a space-eating monster in 300 square feet.

What works:

One hero feature per room. Killer light OR dramatic wall—not both.

Furniture scale matters more than you think. Pieces that look normal in showrooms dominate container spaces. I pick stuff that feels almost too small in regular settings.

Multi-purpose furniture isn't cute—it's survival. Storage ottomans, adjustable tables, murphy beds with desks. Keeps lines clean while using every inch.

Three colors max. Use texture and lighting for interest, not competing patterns and wild colors.

2. Instagram vs Real Life

Social media ruined container design. Clients show me photos of spaces that look amazing online but would suck to actually live in.

Seen floating stairs that terrify anyone carrying groceries. Kitchens where opening the oven blocks the dishwasher. Bedrooms next to living rooms with zero privacy. Great photos, terrible living.

Reality check:

Containers have fixed walls. Every decision affects everything else. No "figure it out later."

Traffic flow becomes critical in tight spaces. I map daily routines—morning coffee, dinner prep, evening chill—make sure layout supports real life.

Storage isn't optional—it's survival. Without enough built-ins, container homes become cluttered disasters fast. I build storage everywhere: under stairs, in walls, under beds, above doors.

Making function fancy:

Kitchen triangle becomes even more important in small spaces. Position sink, stove, fridge for smooth workflow while leaving room for doors and appliances to open.

Living areas need strategic furniture placement. Lightweight pieces that move easy, clear pathways throughout.

3. Backwards Spending Priorities

Breaks my heart because it's so preventable. Watched builders blow serious money on flashy living room features while using contractor-grade crap in kitchens and bathrooms. Completely backwards.

Truth: people judge luxury homes by kitchens and master baths. Most use, most scrutiny.

Why these rooms matter:

Container kitchens work harder—cooking, eating, working, entertaining. Every inch must be perfect without feeling cramped.

Bathrooms are your best shot at real luxury in tight spaces. Amazing bathroom makes 300 square feet feel like a five-star hotel.

Getting it right:

Quality appliances sized for the space. Professional compact often beats big residential that dominates.

Custom cabinets for container dimensions. Max storage, sleek looks. Soft-close everything, pull-out organizers, hidden storage—luxury details that matter.

Spa bathroom, not basic function. Premium tile, high-end fixtures, smart lighting. Floating vanities, glass showers, heated floors—luxury that feels extra special in small spaces.

4. Materials That Look Great, Fail Fast

Container environments are brutal. Steel construction, concentrated traffic, temperature swings expose bad choices quick.

Seen gorgeous hardwood buckle from moisture in months. Beautiful countertops stained permanent. Amazing tile crack from thermal expansion. Not just ugly—expensive failures that kill the luxury vibe.

Container challenges:

Steel conducts heat/cold like crazy. Creates moisture problems if insulation and ventilation aren't right.

Heavy traffic in small spaces means surfaces take way more abuse per square foot.

Sound travels weird through steel. Need careful material selection or create echo chambers.

Smart picks:

Commercial-grade flooring that looks residential. Luxury vinyl plank, quality engineered hardwood, polished concrete. Durability without killing style.

Countertops balance looks with toughness. Quartz gives luxury with better stain/scratch resistance. Natural stone works but needs more maintenance.

Exterior materials handle thermal expansion better. Fiber cement, metal cladding, premium composites weather well while looking good.

5. Climate and Sound Disasters

Nothing kills luxury faster than bad temperatures or annoying noise. Been in container homes that feel like saunas in summer, freezers in winter, where every step echoes.

Happens because people underestimate how different containers are. Steel's heat conduction helps or hurts depending on strategy.

Comfort physics:

Without proper insulation, containers match outside temps fast. Regular insulation often doesn't work for steel.

Sound acts different in steel boxes. Hard surfaces create acoustic environments from echo-heavy to unbearable.

Ventilation critical in sealed spaces. Bad circulation creates stuffiness and moisture that kills luxury living.

Good environments:

High-performance insulation isn't optional. Spray foam gives superior thermal while handling air sealing and moisture. Rigid foam works but needs attention to heat bridges.

HVACneeds precise sizing. Oversized cycles weird, handles humidity poor. Ductless mini-splits often best balance of efficiency and control.

Acoustic treatment built in, not added later. Sound-absorbing materials worked into finishes and furniture.

6. Making Small Feel Smaller

Difference between cozy and claustrophobic often comes down to understanding how eyes and brains work. Bad choices make compact spaces feel like jail cells.

Been in 40-foot containers that felt like closets, 20-footers that felt surprisingly roomy. Difference wasn't size—smart design.

Brain space:

Light colors bounce light around, make spaces bigger. Dark colors suck light, make walls close in.

Vertical lines draw eyes up, make ceilings higher. Horizontal makes wider but lower.

Clear sight lines let eyes travel without obstacles, create openness. Barriers chop visual space.

Tricks that work:

Strategic mirrors literally doublespace feel when reflecting light and views.

Consistent flooring eliminates breaks that chop space. Eyes follow flooring end to end, spaces feel unified.

Furniture with legs creates lightness by letting light flow under. Floor-sitting pieces feel heavy.

Built-in storage to ceiling maxes function, keeps clean lines. Custom eliminates visual mess.

7. Ignoring Outside Space

Biggest missed opportunity. When inside space limited, outdoor becomes super valuable—most treat like afterthoughts.

Why outdoor integration matters:

Limited inside makes outdoor valuable for stuff normally happening inside—eating, entertaining, working.

Industrial can feel cold without natural elements softening.

Luxury living expectations include smooth indoor-outdoor flow. Containers deliver this better than regular construction when done right.

Smooth connections:

Big sliding/folding doors open whole walls, literally expand inside. Fully open, can't tell where inside ends.

Outdoor rooms with specific jobs—cooking, dining, lounging—extend activities outside. Outdoor kitchen doubles cooking/entertaining space.

Matching materials create visual flow, make whole property unified.

Covered areas work regardless weather. Pergolas, awnings, roof extensions allow outdoor use during rain/sun.

Getting Basics Right

Be Honest About Lifestyle

Before falling for Pinterest photos, hard look at how you actually live. Container homes great for some, terrible for others.

Perfect for couples embracing minimal living, travelers wanting low-maintenance, anyone valuing quality over quantity.

Tough for families with teenagers needing privacy, work-from-home folks, anyone struggling with organization.

Pick Containers Smart

Choice affects every decision after. Deserves thought beyond price.

High cube gives extra ceiling height—difference between spacious and cramped. Extra cost usually worth psychological benefits.

Condition affects immediate costs and long-term performance. Newer costs more but pristine starting points. Older might need prep costing more than saved.

Legal Reality

Zoning varies wildly. Some embrace containers, others ban completely. Research before committing.

Permits often work different than regular construction. Some treat as modular, others manufactured housing. Different requirements, costs.

Making Luxury Actually Work

Rethinking Luxury

Traditional luxury about excess—more space, features, everything. Container luxury requires quality, craftsmanship, smart design over volume.

Successful luxury container homes feel like chosen collections, not showrooms. Every element earns place through beauty, function, or both.

Smart spending:

Custom millworkgives luxury while maxing function. Higher per square foot but results justify.

Premium appliances sized right deliver luxury without overwhelming.

High-end finishes in key spots create impressions spreading through whole space.

Tech integration:

Smart systems work especially well because they give luxury convenience without physical space for traditional controls.

Energy management super important. Solar, battery storage, monitoring can create homes making more energy than using.

Hidden Costs Nobody Mentions

Everyone fixates on container price—$6K for 40-footer sounds amazing. That's just entry fee to way more expensive game.

Site Prep Reality

Container needs foundation, not just any. These weigh 8,000 empty, almost 70,000 loaded. Even gutted, serious weight needing proper support.

Watched people try saving with cheap pads, containers shift and settle uneven. Doors won't close, windows crack, structure looks drunk. Proper foundation runs $15K-30K depending on soil and requirements.

Delivery logistics. Getting 40-footer to site isn't furniture delivery. Need crane access, clear paths, often permits. Had client whose delivery cost $8K because needed massive crane over neighbor's house. Container $6K, positioning nearly doubled.

Modification Costs Spiral

Where expenses explode. Cutting holes in containers isn't wood framing. Steel needs specialized tools, expertise, often reinforcement. Every window/door needs proper engineering for structural integrity.

Typical needs 6-8 windows, 2-3 doors. Professional cutting/reinforcement about $2K-3K per opening. Looking at $16K-24K just for holes.

Before installing actual windows/doors. Container-specific cost way more than standard residential because need working with steel framing and thermal expansion.

Insulation Investment

Remember warnings about ovens/freezers? Fixing isn't cheap. Proper insulation costs $8K-15K, quality materials installed right.

Spray foam—essential for containers—runs $3-5 per square foot installed. 40-footer, looking at 2,400 square feet surface including roof. Potentially $12K just insulation.

Some try saving with batt, but seen too many condensation disasters. Nothing less than closed-cell spray foam.

Electrical/Plumbing Challenges

Running utilities through steel needs creativity and expertise. Standard residential doesn't always work drilling through corrugated walls and thermal expansion.

Electrical typically costs 30-50% more because specialized techniques. Plumbing even harder, especially keeping clean aesthetic making containers appealing.

Budget $25K-35K basic electrical/plumbing luxury container, with experienced trades understanding container challenges.

Design Process That Works

Hundreds of projects developed process cutting expensive mistakes, maxing success. Not fastest way, but one that works.

Phase 1: Lifestyle Deep Dive

Before looking containers or drawing anything, weeks understanding how clients live. Document daily routines two weeks—wake up, coffee, cook, work, entertain.

Sounds excessive, but containers don't forgive lifestyle mismatches. Open layout stunning in 3K-square-foot might be disaster for work-from-home needing quiet for calls.

Had client insisted open layout because looked modern. Two months after moving, spent $30K adding walls because couldn't function without separate spaces.

Phase 2: Site Integration

Placement affects everything—views, privacy, solar, winds, utilities. Serious time on site analysis because getting wrong means expensive fixes.

3D modeling test different orientations. How morning sun hit kitchen? Where winter winds? How container relate to existing structures/landscaping?

Often reveals outdoor integration opportunities dramatically expanding functional space. Designed homes where outdoor areas more luxurious than interiors—commercial outdoor kitchens, covered dining with fireplaces, spa outdoor showers.

Phase 3: Container Setup

Where most start, but should be third. Once understand lifestyle needs and site limits, selection becomes clearer.

Single? Multiple? Stacked? Side-by-side? Each has implications for cost, complexity, livability. Simple single might seem easier, but sometimes two smaller give better function.

Recently finished three 20-footers in L-shape. Clients initially wanted single 40-footer, but three-container gave better room separation and outdoor integration for slightly more cost.

Phase 4: Systems Integration

HVAC, electrical, plumbing, data need careful coordination. Unlike regular construction easily modifying during build, containers need precise planning.

Work with mechanical engineers designing systems handling container challenges—thermal bridging, acoustic control, moisture management, limited equipment space.

Smart tech especially important because allows sophisticated control without physical space for traditional controls.

Advanced Pro Tricks

Thermal Bridge Management

Steel conducts aggressively, creating bridges killing even best insulation. Managing separates amateurs from pros.

Use thermal breaks—non-conductive interrupting heat transfer. Might mean isolating from foundation with thermal materials, or special fasteners not conducting through insulation.

Add cost/complexity, but essential for truly comfortable homes. Measured 20-30 degree differences between properly thermal-broken and without.

Acoustic Engineering

Steel naturally noisy—sound bounces off hard surfaces, travels through structure easy. Creating quiet environments needs specialized techniques.

Combination absorption, isolation, masking. Sound-absorbing worked into finishes, isolation preventing transmission, strategic masking with white noise from HVAC/water features.

Most successful strategy creating "room within room" using sound-isolated framing not touching container walls. Adds cost, reduces space slightly, but acoustic improvements dramatic.

Structural Modifications

Incredibly strong original form, but cutting openings needs careful engineering. Work with structural engineers every project ensuring modifications don't compromise safety.

Large openings—floor-to-ceiling glass everyone wants—need significant reinforcement. Frame with steel headers/posts distributing loads properly.

Stacking needs even more careful engineering. Corners designed carrying loads, long walls aren't. Proper stacking needs load transfer systems carrying weight to corner posts.

Luxury Details Defining Success

Custom Millwork/Built-ins

Where container homes really shine. Every inch matters, custom millwork isn't just luxurious—essential for function.

Design built-ins serving multiple jobs while keeping clean looks. Dining banquette with storage underneath, room divider housing mechanical, kitchen island containing water heater and giving workspace.

Higher cost per square foot than regular cabinets, but space efficiency and visual impact justify.

Lighting Strategy

Make or break space feeling. Use layered—ambient, task, accent—creating depth and visual interest making spaces feel larger/complex.

LED strips worked into millwork give even illumination without eating space. Pendants define areas without using floor. Strategic accent highlights textures, creates drama.

Natural light control critical because potential harsh industrial looks. Motorized blinds and smart glass control levels/privacy while keeping clean lines.

Material Authenticity

Work best when materials feel authentic rather than hiding industrial nature. Celebrate corrugated walls rather than covering completely, using industrial as backdrop for warm, luxurious finishes.

Wood, leather, stone, fabric give warmth/texture balancing cool steel. But need genuine—fake finishes look cheap against authentic backdrop.

Source reclaimed whenever possible, not just environmental but aged materials have patina/character complementing perfectly.

Expensive Client Mistakes

Timeline Underestimation

Takes longer than expected, especially done right. Permit approval alone 3-6 months in areas unfamiliar with containers.

Typically quote 12-18 months design to move-in luxury container. Rush always makes expensive mistakes or compromises defining luxury.

Wrong Team Selection

Not all contractors understand. Seen beautiful designs ruined by builders treating like regular construction.

Finding experienced with steel construction, specialized insulation, container challenges essential. Might mean paying more for expertise, but alternative often expensive fixes.

Compromising Key Systems

Budgets tight, clients want compromising insulation, HVAC, acoustic treatment. Exactly wrong places saving money.

Educate early about non-negotiable systems for luxury container living. Skimping fundamentals means never achieving comfort defining luxury housing.

Multi-Container Future

Most exciting projects now involve multiple containers creating homes rivaling traditional luxury in space/amenities.

Campus-Style

Instead fitting everything one container, designing "campuses" where different serve different jobs—living, kitchen, master suite, guest, garage.

Lets each space optimized for specific job while creating interesting outdoor spaces between. Connections become covered walkways, courtyards, outdoor rooms.

Stacked

Two-story opens possibilities more traditional room layouts while keeping container look. Key proper structural engineering and interesting stairs not eating limited floor space.

Recently finished four-container stacked providing 2,400 square feet while keeping relatively small footprint. Upper housed private—bedrooms/studies—lower had social—kitchen/living/dining.

Mixed-Use

Increasing interest container-based mixed-use where residential combines with commercial/recreational. Live-work compounds where home connects workshop/studio.

Work especially well creative professionals needing substantial workspace but wanting efficiency/look of container living.

Where We're Headed

Design evolving crazy fast. What seemed impossible five years becoming routine. Architects push boundaries, manufacturers develop container-specific products, clients become sophisticated.

Tech Integration

Smart becoming built into design rather than afterthought. Advanced climate control, lighting, security, entertainment controlled through phones, eliminating traditional control panels eating wall space.

Experimenting with automated systems adjusting lighting/temperature/ventilation based on occupancy/time/weather. Maintain perfect comfort while maxing efficiency.

Sustainable Systems

Natural platforms for advanced sustainable tech. Solar integrates easily with flat roofs, battery storage fits well mechanical spaces, rainwater collection worked into industrial look.

Working on homes producing more energy than using, processing own wastewater, collecting enough rainwater for complete water independence.

Manufacturing Evolution

Getting sophisticated, specialized companies offering pre-modified designed specifically residential. Arrive with windows/doors/insulation installed, reducing site construction time/costs.

Also seeing purpose-built modules looking like containers but designed ground up for residential, combining aesthetic with optimized function.

Community Development

Moving beyond individual residences to entire communities designed around container aesthetic/sustainable principles. Combine construction efficiency with shared amenities/community spaces.

Consulting 50-unit community where individual homes cluster around shared facilities—community kitchens, workshops, gardens, recreation. Model could revolutionize affordable luxury housing.

But regardless how elaborate, fundamental principles same: respect constraints, max opportunities, never compromise details defining true luxury living.

Done right, containers offer what traditional construction can't: satisfaction creating genuinely unique, environmentally responsible, innovatively designed while delivering comfort/sophistication luxury demands.

Steel boxes once carrying cargo across oceans become vessels for human dreams, aspirations, desire living differently in increasingly homogenized world. That transformation, done properly, creates truly magical.

Exactly why I keep doing this work, even after seventeen years watching people get wrong more than right. When container home succeeds—truly captures vision and delivers experience clients dreamed—nothing quite like it in luxury housing world.

Steel containers once hauling goods across continents evolved into platforms for human creativity and pursuit living authentically in world often feeling mass-produced and soulless. That evolution, handled with skill and respect for both medium and dream, produces absolutely extraordinary results.